What transforms a hardware manufacturer into a name synonymous with trust? At PBI Architectural Hardware, the answer lies in over three decades of unwavering commitment to precision, craftsmanship, and reliability. As a recognized Star Export House and one of India’s most respected hardware manufacturers, PBI blends traditional brass artistry with modern automation to serve global markets.

Founded in 1991, the brand has evolved from a single-product manufacturer into a world-class enterprise known for excellence in architectural hardware manufacturing. Every product—whether a handle, hook, or bolt—tells a story of performance and precision.

This article takes you inside PBI’s process: from material mastery and advanced production to quality control and global OEM partnerships that make its hardware trusted across 15+ countries.

Also Read:

The Foundation of Manufacturing Excellence

Behind every PBI product lies a disciplined process rooted in decades of manufacturing expertise. The Aligarh facility blends traditional craftsmanship with modern engineering, ensuring consistency, durability, and international quality standards.

Key Highlights:

- 30+ years of production excellence

- ISO-aligned quality systems and global certifications

- Continuous R&D and process innovation

- Skilled technicians with generational craftsmanship experience

Key Insight: Decades of precision and discipline have built PBI’s manufacturing strength—turning everyday components into enduring hardware solutions trusted worldwide.

Materials and Multi-Metal Expertise

PBI’s expertise across multiple metals—brass, zinc, aluminum, and stainless steel—defines its flexibility and innovation. Each metal is carefully selected for performance, finish, and cost efficiency, aligning with modern architectural needs.

Material Strengths:

- Brass: Combines elegance with high tensile strength and durability.

- Zinc: Lightweight and cost-effective for diverse fittings.

- Aluminum: Corrosion-resistant and ideal for sleek, contemporary designs.

- Stainless Steel: Resilient for high-traffic and premium projects.

Integrated Secondary Keywords: architectural hardware manufacturing, brass hardware manufacturer, precision metal fabrication

Lesson: PBI’s multi-metal mastery allows it to meet aesthetic, functional, and budgetary requirements across projects of every scale and geography.

End-to-End Production Workflow

From concept to completion, PBI’s vertically integrated process ensures every product meets global standards. Every stage—casting, machining, polishing, finishing, and packaging—is controlled in-house for superior quality and efficiency.

- In-house mold and tooling design for faster prototyping

- Automated machines for consistent casting and shaping

- Multi-stage polishing and buffing for flawless finish

- Dedicated finishing lines for various textures and tones

Takeaway: PBI’s fully integrated system eliminates dependency and error—delivering consistency, precision, and reliability with every shipment.

Advanced Quality Assurance Systems

At PBI, quality is more than a promise—it is a measurable process. Each product undergoes a series of automated and manual tests that verify performance, finish, and endurance.

| Test Type | Objective | Equipment Used |

| Corrosion Test | Ensures finish longevity | Salt Spray Chamber |

| Load Test | Measures mechanical strength | Universal Testing Machine |

| Adhesion Test | Checks coating durability | Cross-Hatch Tester |

| Finish Consistency | Validates gloss and tone uniformity | Spectrophotometer |

Takeaway: Every batch leaving the factory carries the assurance of inspection, precision, and international quality benchmarks.

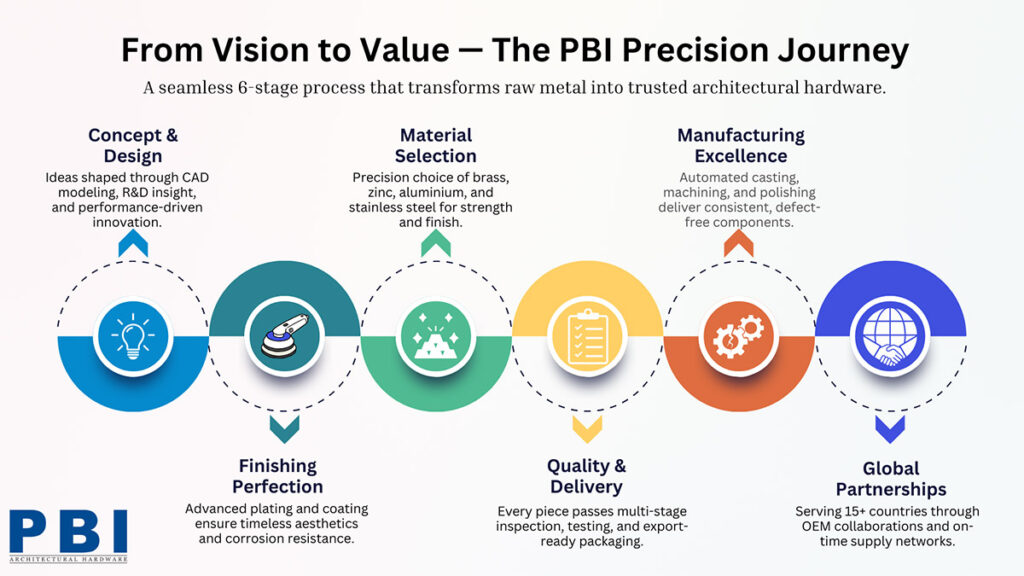

From Vision to Value — The PBI Precision Journey

This journey illustrates how PBI transforms raw metal into trusted architectural hardware. Each stage combines technical precision with craftsmanship, ensuring value creation from design to delivery.

6 Stages:

- Concept & Design: CAD modeling, R&D insights, and performance innovation.

- Material Selection: Precision choice of brass, zinc, aluminum, and stainless steel.

- Manufacturing Excellence: Automated casting and polishing for zero-defect production.

- Finishing Perfection: Advanced plating ensures aesthetic appeal and corrosion resistance.

- Quality & Delivery: Multi-stage inspection and export-ready packaging.

- Global Partnerships: OEM collaborations powering supply to 15+ countries.

Lesson: PBI’s six-stage precision journey is a testament to its ethos—combining design innovation with production integrity to deliver hardware trusted across continents.

OEM/ODM Partnerships and Export Strength

PBI’s OEM and ODM partnerships power international collaborations with leading architectural brands. These long-term alliances are built on flexibility, scalability, and trust.

Highlights:

- 100% Export-Oriented Unit (EOU) recognized by the Government of India

- Global supply network across Africa, Europe, and the Middle East

- OEM hardware production tailored to unique client specifications

- Secure packaging and reliable delivery timelines

Practical Note: PBI’s partnerships prove that quality and dependability transcend borders—helping brands scale globally without compromising on precision.

The Human Element: Craftsmanship Meets Technology

Behind every machine and process are the people who shape perfection. PBI’s artisans and technicians embody decades of experience, transforming metal into art through passion and precision.

Human Excellence Factors:

- Expert artisans skilled in polishing, assembly, and detailing

- Regular skill-upgradation programs for evolving techniques

- Seamless integration between human craftsmanship and automation

- A workplace culture built on pride, precision, and ownership

Lesson: Machines achieve consistency, but it’s the skilled hands at PBI that bring authenticity and warmth to every finished product.

Also Read:

Conclusion

Trust is not built overnight—it is engineered through precision, performance, and purpose. For more than 30 years, PBI has redefined architectural hardware manufacturing by combining design innovation, advanced quality control, and human craftsmanship.

As a globally trusted hardware manufacturer, our mission is simple: to turn metal into lasting value. Each product reflects our belief that strength lies in detail and integrity creates distinction.

For architects, builders, and OEM partners who demand excellence, choose PBI—where every fitting is a promise of reliability, and every finish reflects trust forged in metal.

Partner with PBI — Where Craftsmanship Meets Precision.

For over three decades, PBI Architectural Hardware has been shaping spaces with fittings built to last and designed to inspire. From brass and zinc to aluminium and steel, every product reflects our legacy of trust, innovation, and uncompromised quality.

As a Star Export House with a presence in 15+ countries, we deliver architectural hardware that meets international standards while offering flexibility through OEM and ODM collaborations. Whether you’re developing bespoke interiors or managing large-scale projects, PBI offers the expertise, technology, and reliability your business can depend on.

Let’s craft the future of architectural hardware together.

- 📩 Enquire for partnerships or custom solutions

- 🌐 Visit: www.prabhabrass.com

- 📞 +91 9837077795 | +91 9897012034

- 📧 info@prabhabrass.com

🔗 Connect with Mr. Prashant Kumar Goel on LinkedIn

Crafting Trust in Metal Since 1991 | Made in India, Built to Global Standards